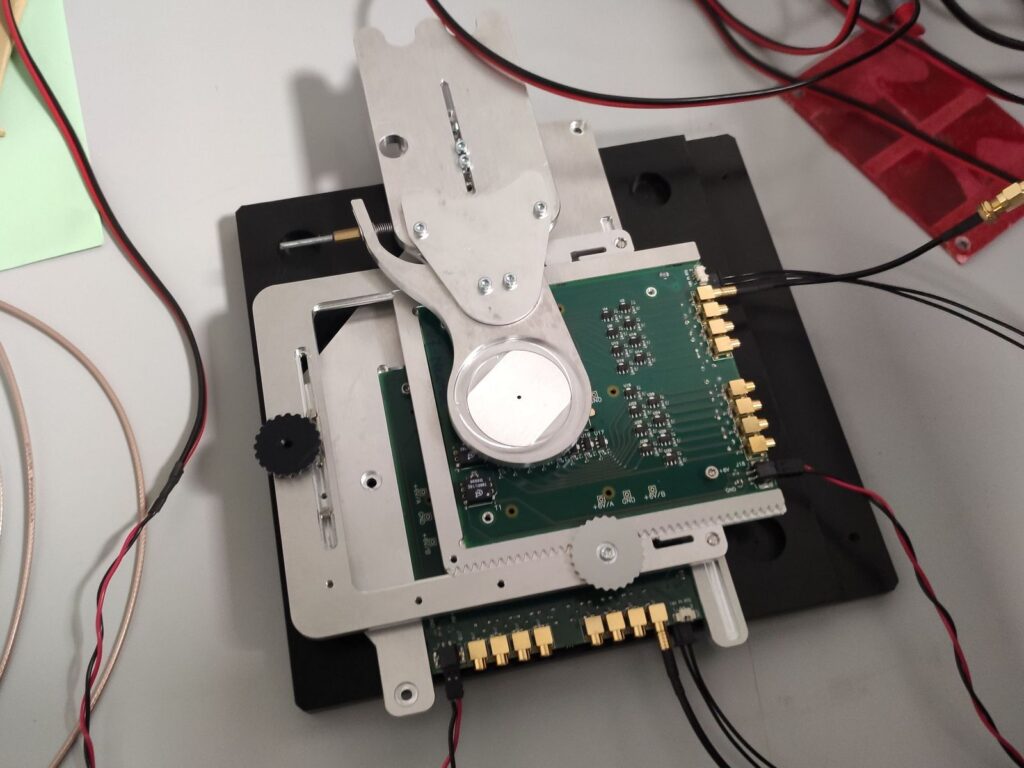

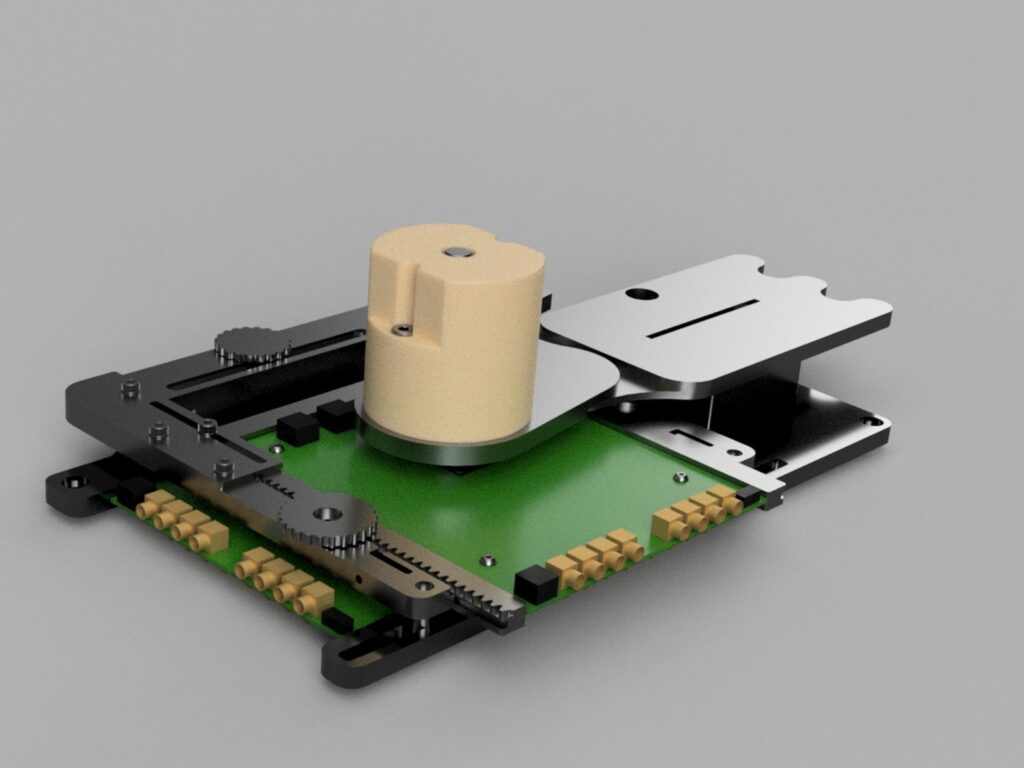

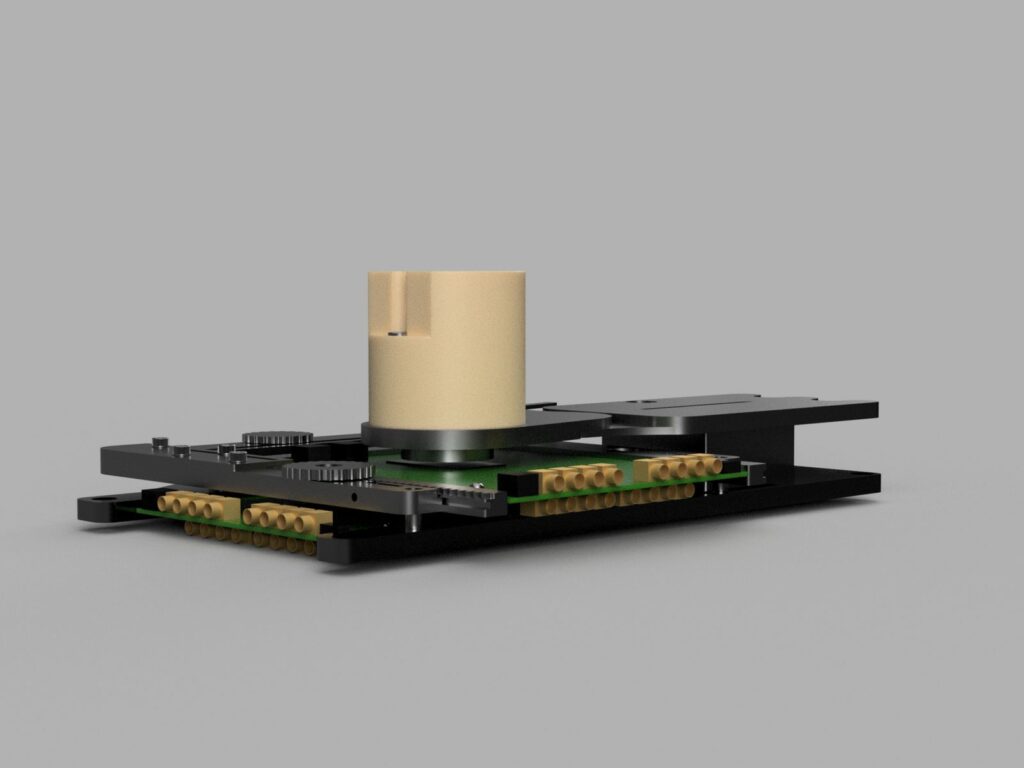

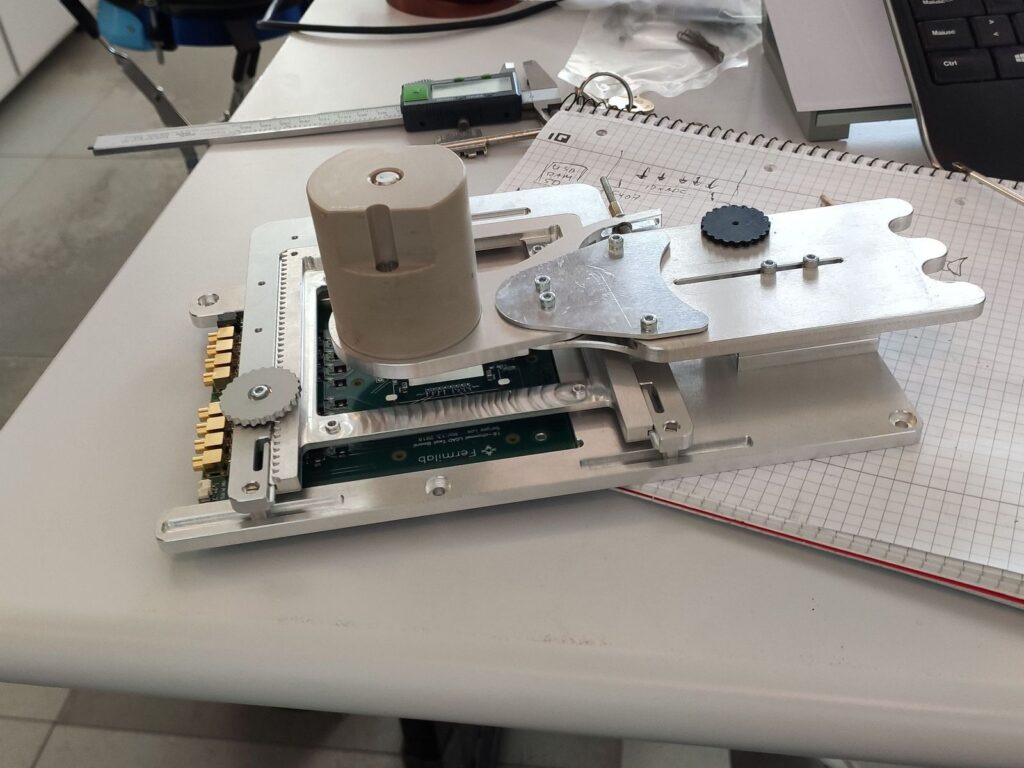

The custom mechanics were designed for the manual 2D alignment of two front-end PCBs with custom sensors onboard. The setup is realized as part of a research activities on beta radiation sensors.

The primary design requirements were as follows: 1) The system needed to allow for precise alignment of two sensors and a beta radiation source along a single axis, with sub-millimeter accuracy. 2) It was crucial to minimize any gaps between the blocks to reduce radiation losses.

The alignment system consists of four independent position controls: two for the middle PCB and two for the top source. The final distances in the configuration are determined by the size of the components and connectors mounted on the PCBs, rather than the mechanics’ geometry.